CeramTec chooses Lindor mixer for very abrasive SiC powder

The Czech factory of the German company CeramTec processes very abrasive Silicon carbide(SiC) for the production of technical ceramics. It was not easy for Iveta Formankova,production manager at CeramTec in Šumperk, to find a wear-resistant mixer for mixing andcoating the very abrasive SiC during her search. She came into contact with Lindor throughthe Internet and discovered the existence of mixers with a ‘gentle touch’: a special mixingtechnique that exerts no force on the powder, which reduces wear to a minimum. Duringmixing a very even liquid coating is possible and a homogenous mass is quickly produced.

The process

Technical ceramic materials are used in industry because of the very specific mechanical properties suchas temperature resistance, wear-resistance, shape retention, insulation value, etc. The ceramic materialsare often abrasive. Silicon Carbide is very abrasive and is therefore used as a grinding medium.

Iveta Formankova explains: “A spray drying installation produces the very abrasive SiC powder. TheLindor mixer then homogenises this SiC powder and coats it with an oil. In the following processpressing, sintering and machining take place to process this into components”.

Finally she wants to add “We discovered Lindor and their special mixers on the Internet and are verysatisfied. The cooperation with Lindor was very good right from the start and the mixer functions withoutany problems.”

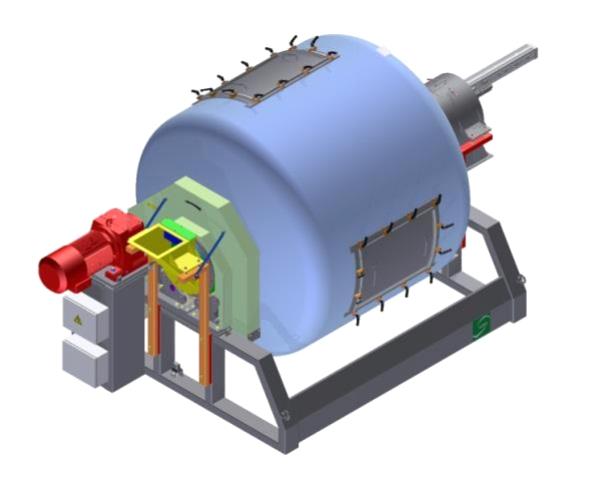

L4000 mixer with special configuration for very abrasive products

The CeramTec mixer is of Lindor type L4000 (4000 litres useful mixing volume – approx. 2000 kg) andconfigured for this very abrasive material.

The most important property of the Lindor mixer for this application is that the actual wear in the mixeris minimal. Three elements create wear: an abrasive substance, movement and force. In this applicationthere is plenty of abrasive substance present in the form of SiC. The movement is also present, thoughmainly in the form of the SiC particles rolling over the SS surface of the mixing drum and over oneanother. The force is however minimal so the wear is also ultimately minimal.

About CeramTec

CeramTec is a company that has been producing technical ceramics for over 100 years. After havingbeen part of the German Chemical group Hoechst in the 80s and 90s it became independent in 1996.The company now has around 3600 employees and branches in 17 countries. CeramTec serves theautomobile, electronics, medical, energy and environmental technology industries as well as mechanicalengineering. In Šumperk among other things gaskets (for example for ships, including the Queen MaryII), sprayers, burner components (up to 1600°C), bearing bushes, armoured elements, etc. are made.

More information on CeramTec can be found on www.ceramtec.cz.