Technology

The Lindor "Gentle Touch" mixer is designed for mixing sensitive, fragile powders, granulates and natural products. Lindor mixers can be delivered with a net product capacity ranging from 10 liters to 25'000 liters per batch.

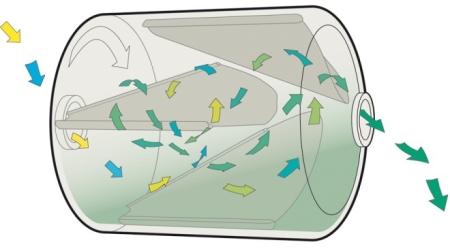

The mixing principle is based on the free flow of product through a slowly rotating drum equipped with specially shaped and oriented vanes. The product is introduced at the axis of the drum through an inlet funnel. The turning motion and gravity gently redistributes the product in a random way and directs the product towards the outlet side of the drum. Here, the accumulation of product causes a backflow: an additional mixing motion.

Key characteristics of "Gentle Touch" Mixing are:

- Minimal of breakage, no frictional heat

- Energy-efficient: Typical installed power: 2.2 kW for 1500 litre mixer

- Excellent homogeneity

- Short mixing times (2 - 5 min.)

- Quick and easy to clean, low maintenance

- Minimal segregation

- Self-emptying

- Horizontal construction

- No moving parts inside the drum

- Variable batch size (10% - 100%)

Areas of application

- Powdered dairy products

- Baby food with e.g. cereals, milk powder, sugar, vitamins

- Breakfast cereals like mueslis, "crueslis" and corn flake products

- Tea, especially leaf teas, herbal teas and teas with liquid flavoring

- Instant drinks like sports drinks, instant coffee, "3 - in - 1" drinks

- Dry soups and sauces with (freeze) dried ingredients

- Natural whole ingredients like nuts, cereals, dried fruits

- Flavors, herbs and salts

- Vitamins, probiotics

- Plastics

- Detergents

- Catalysts

- Metal salts - e.g. Li-ion battery powders

- Ceramics for the electronics and refractory industries

- SAP – Super Adsorbent Powder used in sanitary products like diapers.

- Metal powders - casting additives